The 4 Best Ways Professional Brewers Are Recycling Spent Grain

August 26, 2022

In 2015, New Belgium made 73 million pounds.

And Goose Island generated about 192,000 pounds weekly.

For every 6-pack of beer brewed, we’re left with one pound of this.

What common ingredients are all these breweries producing?

Dubbed “spent grain,” this offshoot of beer making has created a worrisome question for brewers: How to recycle one of the main residuals of their beers?

It’s a challenge, but one that professional breweries across the country are solving in creative ways.

What We’ll Cover in This Piece:

What Is Spent Grain?

Composing 85% of the brewing industry’s waste, spent grain is the crushed starches left over after the grains used to make beer soak in water, extracting sugars and flavors. The liquid goes on to become beer, leaving an enormous amount of grain behind.

The Brewers Association estimates that roughly seventy-two pounds of malt are used per barrel of beer. Last year, the BA reported that independent craft breweries produced 24.8 million barrels of beer. Doing just a quick calculation reveals that breweries created probably somewhere around 1.8 billion pounds of spent grain in 2021. But Daniel Kuzrock, Co-Founder and Chief Grain Officer of ReGrained, a brand under a company called Upcycled Foods that turns spent grain into upcycled food products, says his company estimates that number is much larger—closer to 20 billion pounds of brewers grain in the U.S. per year.

“There is so much supply, so we’ve really been focused on trying to help the market on the demand side to understand how this can be used as an awesome new ingredient,” says Kurzrock. “The next super grain, if you will.”

Because that’s a lot of grain. And as Kurzrock alludes to it doesn’t have to all be a total waste.

As a hefty amount of spent grain piles up, businesses and breweries have responded with sustainable solutions.

And the good news is that it’s not too hard to find a solution that might work for you.

The 4 Best Ways Professional Brewers Are Recycling Spent Grain

From a food brand in San Francisco, which bases its entire line of products on spent grain, to a brewery in Chicago, powering their own equipment by transforming spent grain into energy, new and environmentally conscious ways to dispose of this brewing byproduct have become craftier than ever.

From Seed to Feed

Traditionally, big breweries have sent their spent grain to cattle farmers, who use the nutrient-dense and protein-rich starches to feed their livestock.

This is probably the most common solution for disposing of spent grain. And one you’ll find deployed at many big producers.

Sierra Nevada, the third largest craft brewery in the country, takes advantage of the robust dairy industry surrounding its brewery in Chico, CA. They partner with a third-party company that picks up the spent grain and distributes it to multiple farmers in the area.

While New Belgium benefits from its location in a farm-rich area of Fort Collins, CO. Their 24/7 beer-producing facility contracts with a local farmer, who comes by with his trailer two to three times per day to pick up their spent grain, estimates Katie Wallace, Chief ESG Officer at New Belgium.

And at their Asheville location, the brewery partnered with WNC Communities, an alliance of farmers that purchase spent grain at a reduced cost. The unique setup means that farmers and brewers can work together to increase the economies of scale.

The brewery’s consistent system in both locations means that 100 percent of their spent grain gets recycled. “The measure of success is that it has another life afterwards,” says Wallace.

For big breweries like Sierra Nevada, New Belgium, and others getting spent grain to a farmer can be easier than for a smaller-sized brewery.

Which has led to some ingenuity.

For smaller breweries, just because you might not be able to haul off spent grain to a farmer doesn’t mean you can’t find a way to recycle your leftovers.

From Mash Tun to Mouth

Adapting to these challenges, smaller breweries often partner with independent companies that see spent grain as a commodity instead of as trash.

Many times this means sending spent grain to a third-party business that can repurpose it into some kind of food, baked goods, or edible products, whether for humans or even dogs.

“[Big] brewers are very vocal about making sure their grain gets to cattle farmers or pig farmers so it is not dumped,” said David Crane, the founder of Doggie Beer Bones, one such small business that uses spent grain as the main ingredient in a line of doggie treats. “But the amount [of spent grain] being produced is shocking. Are there enough cows and pigs to eat all that stuff?”

Crane’s enterprise provides an outlet for brewers in the populous Southern California area. Started as a pet project, Doggie Beer Bones began in Crane’s basement, where he baked for a year before attracting the attention of Stone Brewing Co. The brewery partnered with Crane to make “Stone Bones” to sell in the taproom.

Now, Crane snags 400 to 500 pounds of spent grain each month, not only from Stone Brewing, but also from other urban breweries—such as Societe, Harland Brewing, Anderson Valley Brewing Company, Second Chance, Culture Brewing, and Westbrew —to fill his orders of upwards of 2,000 pouches of treats.

Similarly, Kurzrock discovered the cash-making and environment-saving potential of these starches. At UCLA he turned his homebrewing habit into a viable business. As a way to make money for the ingredients he needed to brew, Kurzrock used his extra spent grain to bake and sell twenty loaves of bread.

“The original idea was: What if all the grain from our brewing could make bread? We could sell that and brew for free,” says Kurzrock.

In 2012, Kurzrock ditched the dough for granola bars when he started his San Francisco-based company ReGrained. Their entire line, which now includes baking mixes, chips called “Puffs,” and even pasta, spotlights spent grain.

Although his company can only accommodate a small portion of the spent grain being produced in the United States, Kurzrock sees ReGrained as a part of a revolution—a reformation of mindset when it comes to refuse.

“We want to enable our society to do more with less,” said Kurzrock, mentioning that ReGrained has publicly committed to upcycling 10 million pounds of spent grain by 2025. “In the last five years I imagine we played a key role in waking everyone up to what we’re leaving off the table.”

ReGrained has been a pioneer in building a market for this artisanal approach to valuing resources. Today, Kurzrock mentions he’s seen other companies pop up with a similar vision. For example, Brewer’s Crackers, which makes a line of crackers out of spent grain. Or the Upcycle Grain Project in New Zealand.

And ReGrained itself has only continued to grow.

In the past the company worked with popular San Francisco breweries such as Triple Voodoo, Magnolia, and 21st Amendment. Today, Kurzrock says those relationships have grown, including a fruitful partnership with East Brother Beer Co. in Richmond, CA and even brewing behemoth Coors.

It’s what Kurzrock is putting on the table that’s so important. His motto at ReGrained—“Eat Beer”—encourages people to fill their tummies with an ingredient often misunderstood as trash.

But ovens aren’t the only pieces of machinery revamping these brewing scraps.

From Grain to Grid

Some breweries have really leveled up their use of spent grain.

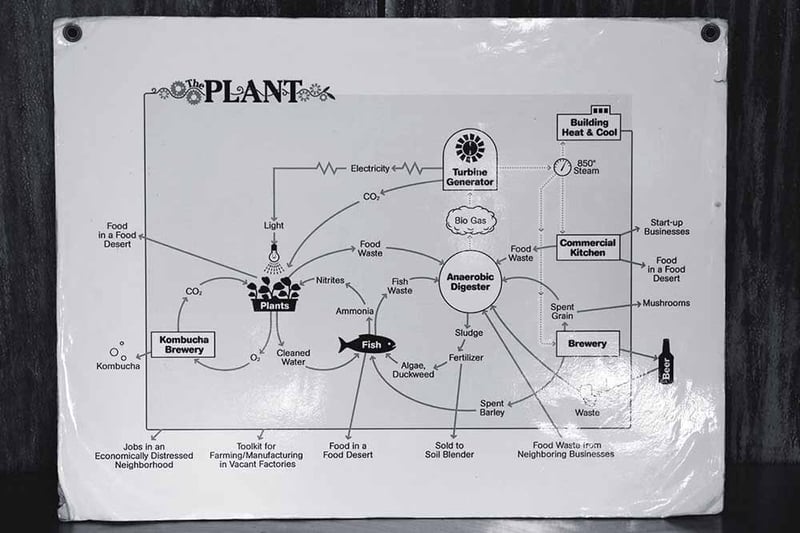

Smaller breweries like Brian Taylor’s Whiner Beer, which opened in The Plant, a net-zero-waste, vertically integrated building, uses a piece of equipment called an anaerobic digester to turn spent grain into fuel.

To explain the science simply, the machine takes organic waste matter—such as spent grain—breaks it down and burps out methane gas. The vapor can then either serve as an energy source for Taylor’s custom-constructed boiler, which he specifically built to run on methane to brew beer, or to power the building. Eventually, Whiner will produce a surplus of energy that can be sold back to the city’s power companies to use on their grid.

“The amount we throw away [to make beer] is pretty insane,” said Taylor when I spoke with him back in 2017.

A former Goose Island brewer, who became more environmentally conscious while working at Goose Island, Taylor wants his Chicago-based brewery to not only change the industry's reckless practices, but also to shift Americans' wasteful perspective. “Even after being used for making beer, spent grain should be looked at as a commodity because there is still value in it,” says Taylor. “It’s not garbage like a piece of plastic.”

Similarly, Alaskan Brewing understands the power of this brewing material. Afterall, as a pioneer on the spent-grain frontier, Alaskan became the first brewery in the country to create fuel from these starches.

Since opening in 1986 on a 10BBL brew system, Alaskan Brewery has always been a leader in repurposing spent grain. Operating at first on a small level allowed the brewery to donate the grain to community gardens. But in 1994, when Alaskan installed a 100BBL brew system to keep up with an increasing demand, production jumped to a 24/7 operation.

“We would have buried the community garden under a mound of spent grain,” said Andy Kline, former marketing manager at Alaskan Brewing back in 2017 when I spoke to him for the first time about spent grain. So they had to figure out something new. An agreement to send the grain to a farmer in Washington State worked for a while but became unprofitable. Situated in a unique location, where a lack of roads requires 90% of everything from bottles to grain to be barged in and out, Alaskan found the amount of time and cost required to ship the mash did not compute.

Finally, in 2008 owner Geoff Larson riffed off an idea he discovered while traveling in Europe. Putting his chemical engineering degree to use, Larson installed a mash press filter. “Instead of acting like a drip coffee filter, the mash press works like an espresso machine or French press,” Kline explained. The device actually squeezes the malts out of the wort, leaving behind a super dry product, which Alaskan can grind into a fine powder.

“The grain looks like sawdust,” said Kline. “It blows away in the wind.” Which got Larson and other engineers thinking: How can we make this burn? Without the mash press filter, the grain takes on a granular, grape nut-like texture which does not ignite efficiently. “It’s like trying to burn a fried egg on a campfire.” said Kline. “It’s just not practical.” In 2013, Alaskan installed a burn chamber that could turn this fine powder into a cleanly incinerating fuel source. The 6 to 8 million pounds of spent grain that the 31st largest American craft brewery makes annually powers a steam boiler, which fuels the entire beer-making process.

Hence Alaskan’s motto, “Beer powered beer.”

So why aren’t more breweries creating this closed loop?

Two reasons: time and money.

Kline explained that the devices needed—such as the mash press filter and burn chamber—are multi-million-dollar pieces of machinery that require special care and attention. He also notes that most breweries spend money on upgrades that lead to a better brew—such as a bottling line or more tanks. “You can make great beer and not have any of the special pieces of equipment we use,” said Kline. Burning capital on something that doesn’t affect the end product can be a hard leap for brewers. But, while Alaskan’s investment may not affect what someone gets out of the bottle, Kline said he has seen nothing but benefits to the brewery’s bottom line.

For Alaskan, pushing the spent grain boundary served a dual purpose: The reward came from a vision not only for a more profitable future, but also for a more eco-conscious one.

From Craft to Compost

For a solution that might be a little friendlier on a brewery’s bottom line, consider donating spent grains to a local garden or farm interested in using it for compost.

A leftover rich in nitrates, sulfates, proteins, and cellulose, spent grain has the power to power up plants. Many fields, gardens, and greenhouses can use spent grain as fertilizer. And in some cases even to grow food like mushrooms.

For small breweries, this is definitely a more viable solution.

Take for example Reuben’s Brews, who donates their spent grain to Tilth Alliance. The local gardening non-profit encourages sustainable practices through responsible farming and gardening, using spent grain as fertilizer to help mushrooms grow.

It’s a practice that even famed, historic breweries such as Brasserie Cantillon in Anderlecht, Belgium have dabbled in. In the past, the iconic brewery has sent some of its spent grain to Eclo (formerly called Le Champignon de Bruxelles), a company growing mushrooms from these brewing leftovers.

It’s a handy solution to a hefty problem. One that every brewery should be paying attention to as we continue to brew into the future.

A Frothy Frontier

Whether used as animal feed, fuel, eaten as granola, baked into a dog treat, or made into compost, Kurzrock optimistically suggests we’re just scratching the surface of upcycling spent grain.

But he cautions that it is an absolutely necessary movement.

“We are in an era where the global food crisis has never been more pronounced, climate chaos is here, supply chains have never demonstrated greater lack of resilience than what we’ve seen over the last couple years,” says Kurzrock. “There is no one solution for all of this, but…there is an opportunity to encourage breweries to pay attention to upcycling not just what they’re doing with their own grain, but how they can also participate through product development and bring interesting ingredients to make unique beers with a sustainable impact.”

After all, as Kurzrock notes, “Waste is a human construct.”

Move Beyond Your Spreadsheets

Have control over your entire inventory and fulfillment processes from anywhere with Ollie. Even integrate with your existing inventory and accounting applications.